Environmental impacts of biomass-to-liquid gasification processes

The production of biofuels by gasification of biomass followed by a synthesis process (BtL-fuels) has been investigated with a life cycle assessment (LCA). The use of different types of biomass (wheat straw, miscanthus and short-rotation wood) has been considered. The LCA investigates the life cycle from seed to tank. The goal was to compare different production routes and show improvement options.

Different partners from the RENEW project supported this work with inventory data for biomass production and conversion technologies. Three automotive industry partners supervise the work on the LCA in a monitoring committee.

The environmental impacts have been investigated for several environmental themes, including land and water use. Agricultural biomass production causes most of the environmental impacts in the life cycle. Thus, the conversion efficiency of biomass to fuel, which ranges between 26% and 69% is most important for comparing the different concepts. The efficiency does not only influence the biomass input. A low efficiency means also higher amounts of air emissions with off-gases and combustion emissions.

Full life cycle from wheel-to-street using Biomass-to-Liquid Fuels

This study elaborates a life cycle assessment of using of BTL-fuels (biomass-to-liquid). This type of fuel is produced in synthesis process from e.g. wood, straw or other biomass. The life cycle inventory data of the fuel provision with different types of conversion concepts are based on the detailed life cycle assessment compiled and published within a European research project.

The inventory of the fuel use emissions is based on information published by automobile manufacturers on reductions due to the use of BTL-fuels. Passenger cars fulfilling the EURO3 emission standards are the basis for the comparison. The life cycle inventories of the use of BTL-fuels for driving in passenger cars are investigated from cradle to grave. The full life cycle is investigated, with the transportation of one person over one kilometre (pkm) as a functional unit. This includes all stages of the life cycle of a fuel (biomass and fuel production, distribution, combustion) and the necessary infrastructure (e.g. tractors, conversion plant, cars and streets).

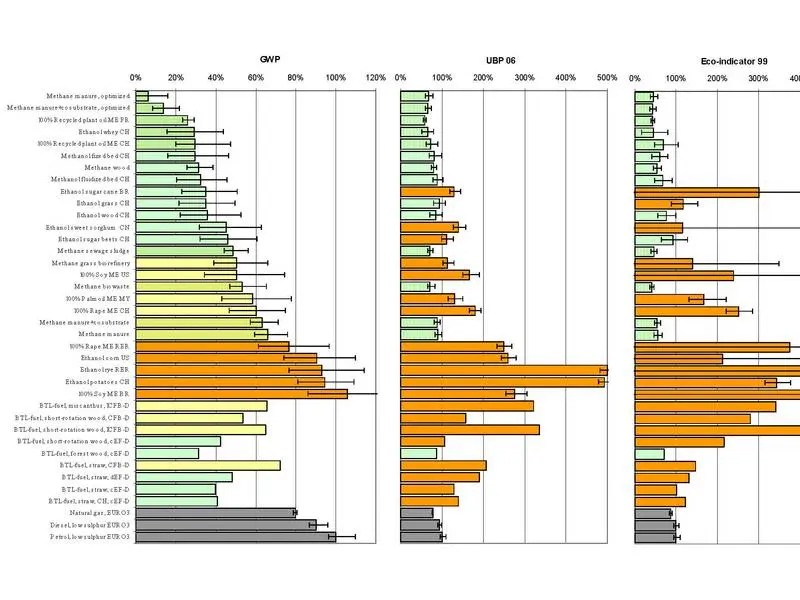

The use of biofuels is mainly promoted for the reason of reducing the climate change impact and the use of scarce non-renewable resources e.g. crude oil. The possible implementation of BTL-fuel production processes would potentially help to achieve this goal. The emissions of greenhouse gases due to transport services could be reduced by 28% to 69% with the BTL-processes using straw, forest wood or short-rotation wood as a biomass input. This is lower than the 90% CO2-reduction claimed in earlier studies. The reduction potential concerning non-renewable energy resources varies between 37% and 61%.

A previous study showed that many biofuels cause higher environmental impacts than fossil fuels if several types of ecological problems are considered. The study uses two single score impact assessment methods for the evaluation of the overall environmental impacts, namely the Eco-indicator 99 (H,A) and the Swiss ecological scarcity 2006 method. The transportation with the best BTL-fuel from short-rotation wood has only slightly higher environmental impacts than the reference under an evaluation with the ecological scarcity 2006 method. BTL-fuel made from agricultural by-products like straw can achieve environmental impacts similar to petrol if the Eco-indicator 99 (H,A) is evaluated. BTL-fuel from forest wood is an interesting option to reduce the greenhouse gas emissions and environmental impacts.

This LCA study shows that it is possible to produce BTL-fuels, which are competitive to fossil fuels from an environmental point of view. But, it also shows that for the use of agricultural biomass, further improvements in the life cycle would be necessary in order to avoid higher environmental impacts than for fossil fuels. There is no general conclusion concerning the comparison of BTL-fuels with other renewable or fossil fuels, due to the variety of different conversion concepts and possible biomass resources.

Publications

The LCA study has been elaborated within the following deliverables. All parts of the LCA have been reviewed according to the ISO 14040 standard:

Jungbluth, N. & Schmutz, S. 2007: Inventory dataset: EcoSpold/Gabi/Excel. Deliverable: D 5.2.9, ESU-services Ltd., Uster. (download of electronic data)

Jungbluth, N., Frischknecht, R., Faist Emmenegger, M., Steiner, R., Tuchschmid, M. 2007: Life Cycle Assessment of BTL-fuel production: Life Cycle Impact Assessment and Interpretation. Deliverable: D 5.2.10.

Jungbluth, N., Frischknecht, R., Faist Emmenegger, M., Steiner, R., Tuchschmid, M. 2007: Life Cycle Assessment of BTL-fuel production: Inventory Analysis. Deliverable: D 5.2.7.

Jungbluth, N., Frischknecht, R., Faist Emmenegger, M., Tuchschmid, M. 2007: Life Cycle Assessment of BTL-fuel production: Goal and Scope Definition (revised). Deliverable: D 5.2.2, ESU-services Ltd., Uster.

Jungbluth, N., Frischknecht, R., Faist Emmenegger, M. 2004: Review of LCA case studies for BTL-fuel production. Deliverable: D 5.2.1 ESU-services Ltd., https://www.renew-fuel.com, Uster.

Jungbluth, N., Frischknecht, R., Faist Emmenegger, M., Steiner, R., Tuchschmid, M., Schmutz, S. 2007: Life Cycle Assessment of BTL-fuel production: Final Report. Deliverable: D 5.2.15., ESU-services Ltd., Uster. (20 pages summary of all results)

First European Summer School on Renewable Motor Fuels with a lecture on LCA.

All LCA results were presented during the Second European Summer School on Renewable Motor Fuels.

The use of BTL-fuels in passenger cars has been compared with fossil diesel over the full life cycle (well-to-wheel). Commissioned by the European Commission, Federal Office for Education and Science (Bundesamt für Bildung und Wissenschaft) and Swiss Federal Office of Energy (Bundesamt für Energie).

Jungbluth, N., Büsser, S., Frischknecht, R., Tuchschmid, M. 2008: Ökobilanz von Energieprodukten: Life Cycle Assessment of biomass-to-liquid fuels. Programm Biomasse No. 280006, ESU-services Ltd. im Auftrag des Bundesamtes für Energie, Bundesamt für Umwelt und Bundesamt für Landwirtschaft, Berne, CH